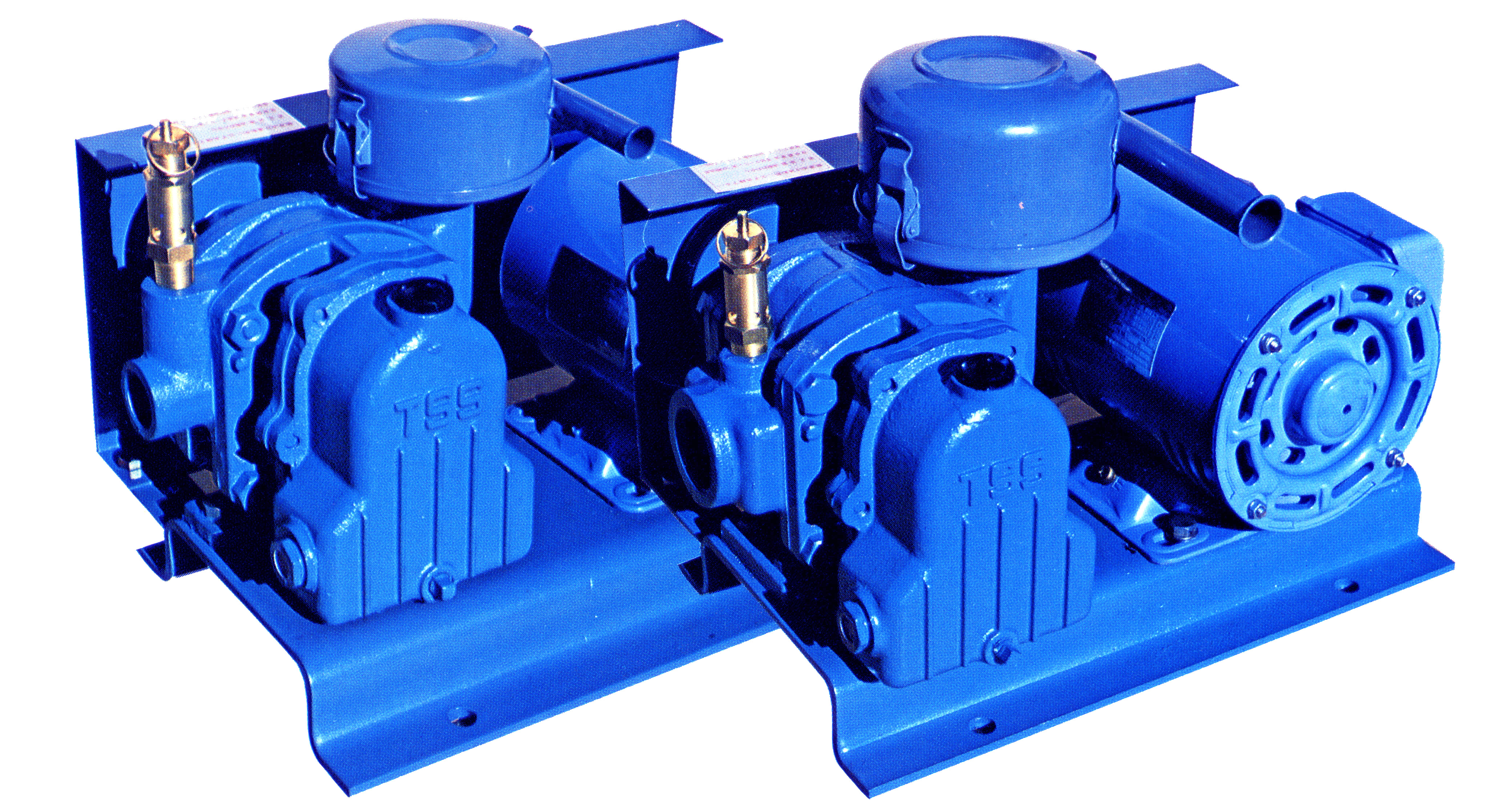

Roots Air Blower

ত্রিপল লোব রুটস ব্লোয়ার

What is a Roots Blower?

A roots blower is a type of positive displacement blower that uses two rotors to move air or gas through a system. The rotors are designed with lobes that mesh together, creating pockets that trap and move air from the intake side to the discharge side of the blower. This continuous motion of air or gas creates a constant flow rate that is ideal for many industrial applications.

Benefits of Roots Blowers

Roots blowers offer several benefits that make them a popular choice for industrial applications in Bangladesh. Some of the key benefits include:

-

High flow rates: Roots blowers can move large volumes of air or gas quickly and efficiently, making them ideal for applications that require high flow rates.

-

Low maintenance: Roots blowers have few moving parts, making them easy to maintain and repair. They also have a long lifespan, reducing the need for frequent replacements.

-

Energy efficiency: Roots blowers are designed to be energy-efficient, helping to reduce operating costs and improve overall sustainability.

-

Versatility: Roots blowers can be used in a wide range of industrial applications, including wastewater treatment, cement production, pneumatic conveying, and power generation.

Applications of Roots Blowers in Bangladesh

Roots blowers are used in various industries in Bangladesh, including:

-

Wastewater treatment: Roots blowers are used in wastewater treatment plants to provide aeration and mixing. This helps to break down organic matter and promote the growth of beneficial bacteria.

-

Cement production: Roots blowers are used in cement production to move air through the kiln and cool the clinker after it has been heated.

-

Pneumatic conveying: Roots blowers are used in pneumatic conveying systems to move dry bulk materials such as cement, flour, and sugar.

-

Power generation: Roots blowers are used in power generation to move air through the combustion chamber and cool the turbine.

-

Follow the manufacturer's recommended maintenance schedule: The manufacturer's maintenance schedule should be followed closely to ensure that the blower is serviced and inspected regularly. This includes tasks such as lubrication, bearing inspections, and cleaning.

-

Keep the blower clean: Dirt and debris can cause damage to the blower's components and reduce its efficiency. Regular cleaning of the blower's exterior and surrounding area can help to prevent this from happening.

-

Check and replace filters regularly: Filters are an essential component of the blower's intake system, and they need to be checked and replaced regularly to prevent damage to the blower's components and maintain its efficiency.

-

Monitor the blower's operating conditions: The blower's operating conditions should be monitored regularly to ensure that it is running within its specified parameters. This includes checking the discharge pressure, temperature, and noise levels.

-

Keep a record of maintenance activities: Keeping a record of maintenance activities, including when they were performed and what was done, can help to ensure that the blower is being properly maintained and provide a history of its maintenance activities.

-

Use genuine parts and lubricants: It is important to use genuine parts and lubricants recommended by the manufacturer to ensure that the blower is functioning as intended and to maintain its warranty.

By following these best practices, users can help to maintain their roots blower's efficiency and reliability, extend its lifespan, and avoid costly repairs and downtime.

#রুটস ব্লোয়ার

Contact us for technical consultation or quotation today!