5 Vital Questions To Ask Before Purchasing A Vacuum Pump

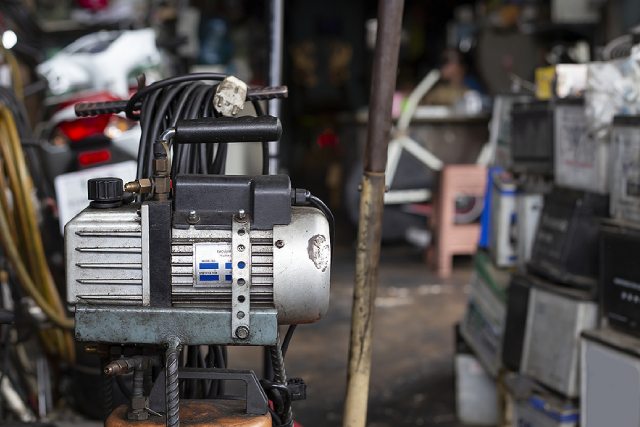

Vacuum pumps have an expansive range of applications in a variety of industries, such as electric power, mining, chemical industry, plastic industry, medical industry, and pharmaceuticals. A vacuum pump is essentially a device that discards air particles or gas molecules from a sealed volume in order to achieve a difference in pressure and create a partial vacuum.

There are different types of vacuum pumps. Each of these pumps has a distinct application in certain industries. When choosing a vacuum pump, one should take into account several factors, particularly the pump’s intended use. Below are some of the essential questions that purchasers should ask before buying a vacuum pump in order to ensure that they get the right type for their application.

Operating pressure refers to the pressure that is required for a certain application or process, while flow pertains to the volume of air that the vacuum pump can move over time. Understanding a vacuum pump’s operating pressure and flow is necessary to ensure its proper and efficient application.

Many people often confused a vacuum pump’s operating pressure with its ultimate pressure. Ultimate pressure is basically the deepest operating pressure that a pump can generate. If the equipment specifies that the ultimate pressure is 0.01 mbar, this does not automatically mean that it is the normal operating requirement for an application. Knowing the difference between operating and ultimate pressures before purchasing a vacuum pump is vital.

Similarly, purchasers should also know the distinction between SCFM and ACFM. These are the units in which vacuum flows are usually expressed. SCFM is a unit of flow at a particular set of conditions that assumes the temperature to be at 60°F, the pressure at 14.7 psia, and the relative humidity at 0. On the other hand, ACFM is the unit of flow at actual conditions. Conflating these terms can result in a greatly oversized or undersized equipment.

2. What are the evacuation time and pressure parameters?Evacuation time refers to the amount of time that it takes for the required pressure level to be achieved. Whether one requires two seconds or ten seconds will totally depend on the vacuum pump’s application. For instance, chemical processes will demand different parameters from the processes in food industries.

In some frail applications, drawing a vacuum too rapidly can result in significant damage. For example, the suction cups that raise eggs from a factory’s conveyor belt and put them into cartons cannot draw too rapidly, as doing so will most likely break the shells. In some applications, on the other hand, a high level of vacuum is needed to execute various processes successfully. Ultimately, buying an equipment with incorrect evacuation time and pressure parameters can adversely affect product quality.

3. Is there a risk of contamination?Before buying a vacuum pump, it is necessary for a purchaser to discuss with their provider how wet or dry their application is. Since vacuum pumps pull the air toward the system instead of pushing it away, wet and dry applications each poses particular risks to a pump system. With wet applications, there is a possibility that moisture will be pulled back into pump. On the other hand, dry applications can result in some materials ending up in the pump without adequate filtration.

If any type of contamination to the pump system occurs, a number of unfavourable effects can arise. For one, the oil used for cooling, lubrication, and sealing can be damaged and can cause the pump to run on a less-than-efficient level. Contamination can also result in more necessary maintenance and a shorter lifespan for the pump system.

4. Is there any temperature-related consideration?Like the wet and dry nature of a process, the temperature of its application can also have a significant impact on the health of a vacuum pump system. Extreme temperature can particularly affect the functionality of a vacuum pump. Without necessary protection, high heat can destroy the oil responsible for cooling the system, lubricating the pump, and making a seal, while excessively cool temperatures can make the oil thicker and more viscous. In either case, complications to the pump are likely to occur.

5. Is there any space or location consideration?

Many purchasers often overlook space and location considerations when buying a new vacuum pump. Most of them usually focus on the cost, connectivity, and functionality of the equipment. While these considerations are undoubtedly essential, none of them will matter if the vacuum pump will not fit in its intended facility. Hence, before making a purchase, one should necessarily communicate with their vacuum pump provider about any limited floor space or narrow doorways.

Conclusion

Not all vacuum pumps are equal. They come in a variety of types for different applications and industries. Selecting the right kind of vacuum pump is important to make sure that it satisfies its intended application. There are other considerations such as getting a custom pump instead of a ready-made pump as well. To be sure, purchasers are highly advised to seek the advice and recommendations of professionals or companies that provide reliable pump repair services in Singapore before buying a vacuum pump. With the right information at hand, one can ensure the cost-effectiveness of their vacuum pump purchase.