Custom Pump Solutions: Its Advantages Over Ready-Made Pumps

Unlike off-the-shelf pump solutions, custom pump designs are surrounded by many common misconceptions that could mislead clients. For instance, small business owners believe they do not need custom pumps since their operations are too small to consider investing in them. Furthermore, when hearing about "custom", others immediately associate it as expensive. Moreover, many may think that a custom pump solution will not significantly differ from an off-the-shelf pump, making them not worth the time, money, or effort.

Generally, these business owners and pump operators are not in the know. In other words, they are not privy to how a custom pump is substantially better than what they are using or how a custom one can positively affect their operations and bottom line. Thus, for those that still rely on off-the-shelf pumps, let us discuss why it is time to consider getting a pump solution customised and made to your specifications and applications.

System design and configuration

Ready-made standard high-pressure pumps are designed to accommodate the broadest possible range of applications. The manufacturers of these pumps often claim and assume that their solution works for anything, from pest control to agricultural fertigation, for example. Ultimately, they all require misting.

However, proper droplet sizes and coverage for each misting application will differ in the recommended PSI, GPM, nozzle, and other parts. Hence, it is near impossible to achieve the desired precision without using a custom solution.

Moreover, the products used will also have varying chemical compositions and the materials used to manufacture the pump – PVC, stainless steel, anodised aluminium, ceramic, etc. – which determines compatibility. Even something as simple as the seals and O-rings' material will make all the difference, especially when harsh chemicals are involved. Chemical compatibility is only one of many factors in pump design that will determine how durable and long-lasting the solution will be.

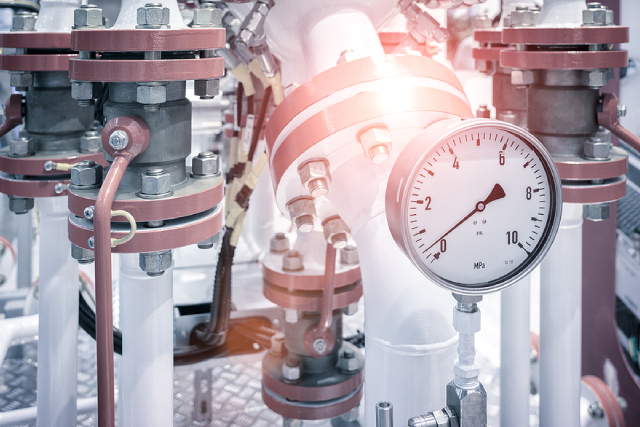

Another critical consideration is the proper configuration of a pump solution into a system. Placement and correct selection of nozzles, regulators, filters, pressure gauges, hoses, power supplies, plumbing, and other components all play vital roles in the performance and durability of a pump. Since custom pump solutions are specifically designed for a particular set of specifications, chemicals, and applications, business owners no longer have to settle for inferior or meagre performance, costly wasted pumps, or disruptive pump failures.

Pricing of custom pumps

Although pricing may be surprising as one of the advantages of custom pumps, it is undoubtedly true despite commodity pumps being cheaper on the surface - for the initial price tag, that is. It is essential to look at the bigger picture and see the total cost of owning a pump. In this case, business owners are likely to find that custom-made pumps cost far less in the long term.

Choosing a custom pump means fewer wasted products, lesser pump replacements, and prevent fines from environmental regulation violations. Most importantly, customers will be happier with a custom pump's performance and results. Businesses must also consider the average duration and frequency of downtimes experienced with their off-the-shelf pump solution. Apart from losing revenue for every minute gone doing pump servicing in Singapore, the additional labour costs further compound the losses.

Right-sized for the application

Off-the-shelf pumps rarely produce accurate pressure, flow, and output necessary for a given application, as generally, many commodity pumps are too big and powerful for many commercial uses. By engaging a custom pump manufacturer, business owners can be sure that their needs and pain points will be thoroughly assessed, guaranteeing that their pump comes with the right PSI and GPM they need for their application.

In short, using a pump in the wrong size and configuration is a sure-fire way for businesses to lose money in daily operations. As such, companies that currently use off-the-shelf pump systems should consider switching to a custom pump as soon as possible to avoid losing more time and money.

How To Know Which Pump To Use

There is no denying that there are times wherein a stock pump is an excellent choice. However, without sufficient engineering knowledge, it may prove extremely difficult to determine which materials, pressure, flow, hoses, amperage and other factors will yield the results required.

As such, it is better to reach out to a custom pump manufacturer and have them assess your current setup to determine the pump solutions your business needs immediately. It is also important to be aware of the causes of high pump noise levels and when it should be a cause for concern.

Conclusion

Opting for commodity pumps may seem better on the surface, but apart from their initially cheap price tag, they often come with many shortcomings, maintenance and performance-wise. In contrast, having a pump system customised for your business applications means getting a piece of efficient equipment best suited for them, reaping numerous benefits that ultimately improve the business's operation uptime, bottom line, and use of resources.