How To Diagnose Common Vibration Issues In Centrifugal Pumps

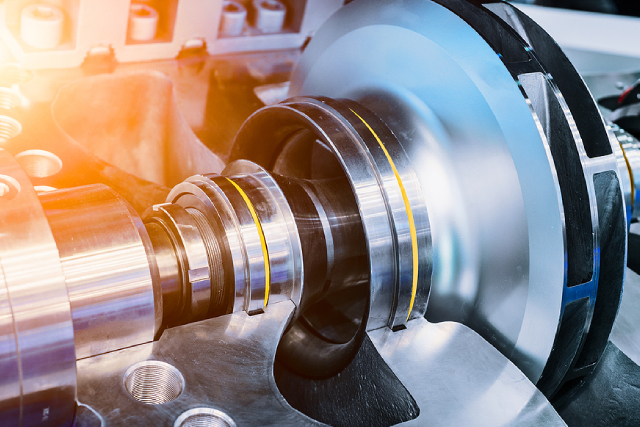

Centrifugal pumps are vital components in many industrial and commercial systems, including water pumps and screw compressors. They play a crucial role in maintaining fluid movement and pressure within these systems. However, one of the most common and disruptive issues that operators face is vibration. Understanding and diagnosing these vibrations are essential for ensuring the optimal performance and longevity of centrifugal pumps.

In this article, we will explore common causes of vibration in centrifugal pumps and provide practical tips for diagnosing and addressing these issues.

Understanding centrifugal pump vibration

Centrifugal pump vibration is often a symptom of underlying problems within the pump or its associated components. Vibrations can lead to premature wear and tear, reduced efficiency, and even catastrophic failure if not addressed promptly. Identifying the source of the vibration is the first step in diagnosing and rectifying the issue.

Common causes of vibration

1. Imbalance: One of the most frequent causes of vibration in centrifugal pumps is an imbalance in the rotating assembly. This can occur due to uneven wear or damage to the impeller, or if there is an accumulation of debris on the impeller. An imbalanced pump can cause excessive vibration that may be felt throughout the system, affecting not only the pump but also connected components like water pumps and screw compressors.2. Misalignment: Misalignment between the pump shaft and the motor shaft can lead to vibrations. This issue is often caused by improper installation or changes in the system’s alignment over time. Misalignment can cause uneven loading on the bearings, leading to vibration and potential damage.

3. Cavitation: Cavitation occurs when the pump operates under conditions that cause the fluid to vaporise, creating vapor bubbles. When these bubbles collapse, they can generate shockwaves that result in vibration. Cavitation is usually a result of inadequate NPSH (Net Positive Suction Head), improper pump selection, or excessive flow rates.

4. Worn Bearings: Bearings are crucial in supporting the rotating elements of a pump. Over time, bearings can wear out due to continuous operation, inadequate lubrication, or contamination. Worn bearings can lead to increased vibration and noise, affecting the pump’s overall performance.

5. Hydraulic Forces: Imbalances in the hydraulic forces within the pump can also cause vibration. This can be due to issues such as flow turbulence, improper impeller design, or blockage within the pump.

Diagnosing vibration issues

1. Visual inspection: Begin with a thorough visual inspection of the pump and its associated components. Look for signs of wear, damage, or misalignment. Check the pump’s mounting and ensure that it is securely anchored. Inspect the impeller for any visible damage or debris that could be causing imbalance.2. Vibration analysis: Utilise vibration analysis tools to measure and analyse the vibration levels. Devices such as vibration meters or accelerometers can provide valuable data on the amplitude and frequency of the vibrations. Compare these readings with standard vibration limits to identify whether the levels are within acceptable ranges.

3. Alignment checks: Use laser alignment tools or dial indicators to check the alignment between the pump shaft and the motor shaft. Proper alignment is crucial for reducing vibration and ensuring smooth operation. Misalignment should be corrected by adjusting the pump or motor position as needed.

4. Bearing inspection: Check the bearings for signs of wear or damage. This can be done by measuring the temperature and vibration levels of the bearings. Excessive heat or unusual vibration patterns can indicate bearing issues. Replace bearings if they are found to be worn or damaged.

5. Cavitation detection: Monitor the pump’s suction conditions and operating parameters to determine if cavitation is occurring. Look for signs such as fluctuating discharge pressure or unusual noise. Adjust the operating conditions or modify the pump system to alleviate cavitation.

6. Hydraulic testing: Perform hydraulic tests to assess the flow and pressure conditions within the pump. Ensure that the pump is operating within its designed parameters and that there are no blockages or restrictions affecting the flow. Adjust the flow rate or pump selection if necessary.

Addressing vibration issues

Once the cause of the vibration has been identified, take appropriate measures to address the issue. This may involve:

- Balancing the pump: If imbalance is the cause, balance the impeller or rotating assembly. This may require professional balancing services to achieve precise results.

- Realigning the pump: Correct misalignment by adjusting the pump and motor positions. Proper alignment will help reduce vibration and prevent further damage.

- Replacing worn components: Replace worn bearings or damaged parts as needed. Ensure that new components are properly installed and lubricated.

- Adjusting operating conditions: Modify operating conditions to address cavitation or hydraulic issues. This may involve adjusting flow rates, improving suction conditions, or selecting a different pump model.

- Regular maintenance: Implement a regular maintenance schedule to monitor the condition of the pump and its components. Regular inspections and preventive maintenance can help identify and address potential issues before they lead to significant problems.

Conclusion

Diagnosing and addressing vibration issues in centrifugal pumps is crucial for maintaining the efficiency and longevity of these essential components. By understanding common causes of vibration and utilising appropriate diagnostic tools and techniques, operators can effectively manage and resolve these issues. Whether dealing with water pumps, screw compressors, or other centrifugal pump applications, a proactive approach to vibration management will contribute to optimal performance and reliability. Regular maintenance and timely intervention will ensure that your centrifugal pumps continue to operate smoothly and efficiently.