Positive Displacement Pumps: A Complete Guide For Beginners

When it comes to moving fluids, Positive Displacement (PD) pumps play a crucial role in various industries. Whether it's transferring water, oil, or chemicals, understanding the fundamentals of PD pumps is essential for beginners entering the field. In this comprehensive guide, we'll delve into what Positive Displacement pumps are, how they work, their types, applications, and maintenance tips.

What are Positive Displacement Pumps?

Positive Displacement pumps are mechanical devices designed to move fluid by trapping a fixed amount of it and then displacing it into a discharge pipe. Unlike dynamic pumps, which rely on centrifugal force, PD pumps use reciprocating or rotary mechanisms to achieve this. This results in a more controlled and consistent flow rate, making them suitable for various applications.

How do Positive Displacement Pumps work?

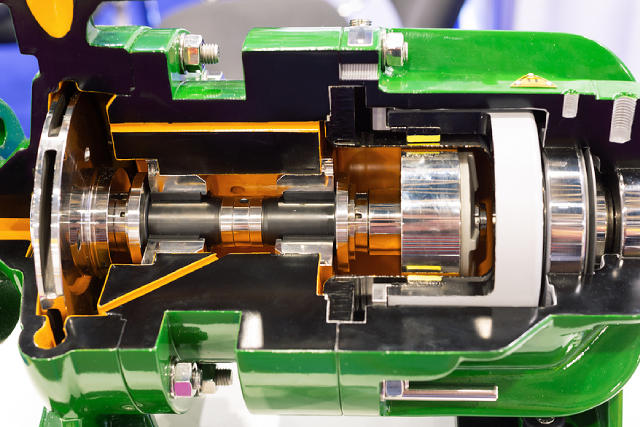

The operation of Positive Displacement pumps is based on the principle of trapping and displacing fluid within a confined space. In reciprocating pumps, this is achieved through the back-and-forth motion of a piston or diaphragm, while rotary pumps use rotating elements such as gears, lobes, or screws to accomplish the same. As the pump cycles, it continuously traps and expels fluid, creating a steady flow.

Types of Positive Displacement Pumps

Positive Displacement pumps come in various types, each suited to specific applications and operating conditions. Common types include:

Reciprocating Pumps: These pumps use a piston or diaphragm to create pressure and move fluid.

Rotary Pumps: Rotary pumps operate by rotating gears, lobes, vanes, or screws to displace fluid.

Gear Pumps: Gear pumps utilise interlocking gears to push fluid from the inlet to the outlet.

Lobe Pumps: Lobe pumps use rotating lobes to trap and transfer fluid.

Screw Pumps: Screw pumps, also known as progressing cavity pumps, employ a helical rotor to move fluid through a screw-like mechanism.

Each type has its advantages and limitations, depending on factors such as viscosity, pressure, and flow rate requirements.

Applications of Positive Displacement Pumps

Positive Displacement pumps find applications across a wide range of industries, including:

Oil & Gas: For transferring crude oil, refined products, and drilling fluids.

Chemical Processing: Handling corrosive chemicals, solvents, and polymers.

Water Treatment: Pumping wastewater, sludge, and chemicals in treatment plants.

Food & Beverage: Transferring viscous fluids such as syrups, sauces, and dairy products.

Pharmaceuticals: Metering and dosing precise amounts of medicines and reagents.

These pumps are valued for their ability to handle varying viscosities, pressures, and temperatures, making them versatile in demanding environments.

Maintenance Tips for Positive Displacement Pumps

Proper maintenance is essential to ensure the efficient and reliable operation of Positive Displacement pumps. Here are some key tips:

Regular Inspections: Check for leaks, wear, and damage to pump components.

Lubrication: Ensure adequate lubrication for moving parts to prevent excessive friction and wear.

Seal Replacement: There is no denying the importance of seals in positive displacement pumps. Replace seals and gaskets as needed to prevent leakage.

Cleaning: Flush the pump and piping system regularly to remove debris and buildup.

Monitoring: Keep an eye on performance metrics such as flow rate, pressure, and temperature to detect any abnormalities early.

By following these maintenance practices, operators can extend the lifespan of their Positive Displacement pumps and avoid costly downtime.

Conclusion

Positive Displacement pumps are indispensable tools in various industries, offering precise control and reliable performance in fluid transfer applications. Understanding their principles of operation, types, applications, and maintenance is crucial for beginners entering the field.

For reliable screw compressors or pump solutions and expert advice, consider partnering with Winston Engineering, a trusted supplier specialising in a wide range of pump systems, from water pumps and vacuum pumps to gear pumps. Additionally, if you're looking for a Graco distributor in Singapore, Winston Engineering is your go-to source.